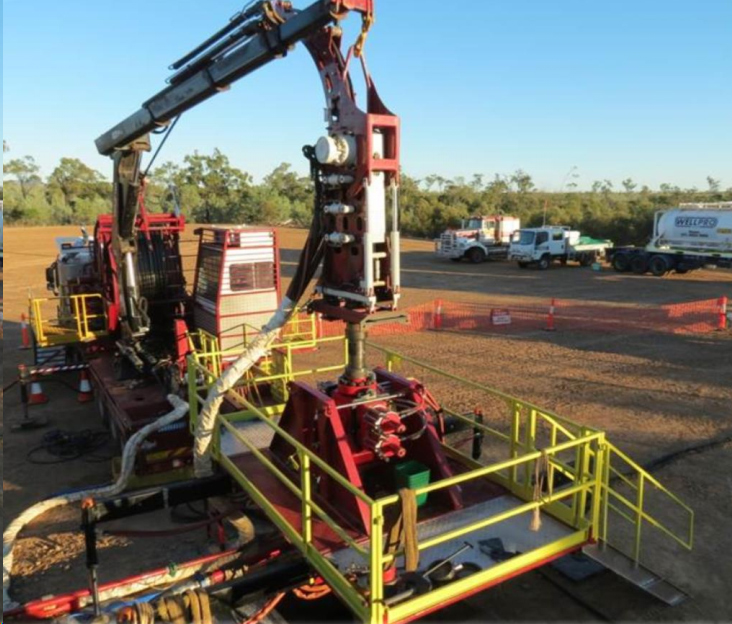

Wellpro’s coiled tubing units have been designed and manufactured by Wellpro for local conditions and regulations. Our truck mounted CTU’s are highly mobile and offer the smallest operational footprint in the sector.

Our coiled tubing units are capable of the following operations:

Carrier

Injector Unit

Control Cabin

Data Acquisition

Coil Tubing Reel Capacity

Unit Safety Features

Single Contractor Option for Well Plug & Abandonment

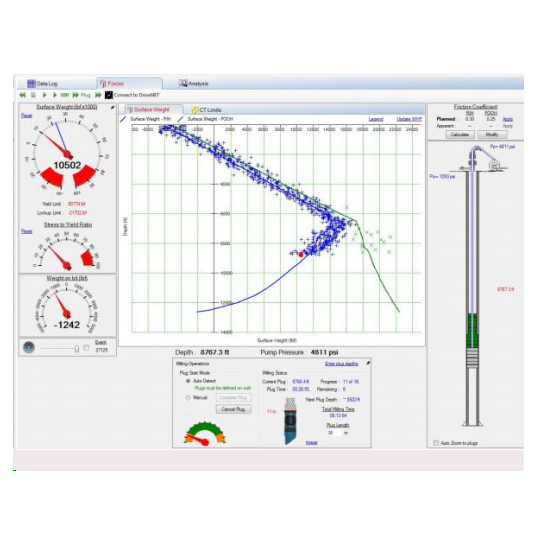

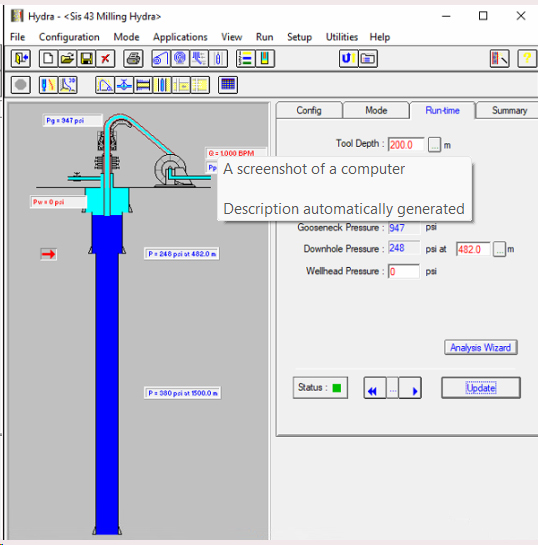

Wellpro’s Coiled Tubing Simulator is theworld’s leading commercial modelingsoftware, which allow us to provide solutions in job design

Features/Benefits

Job Design

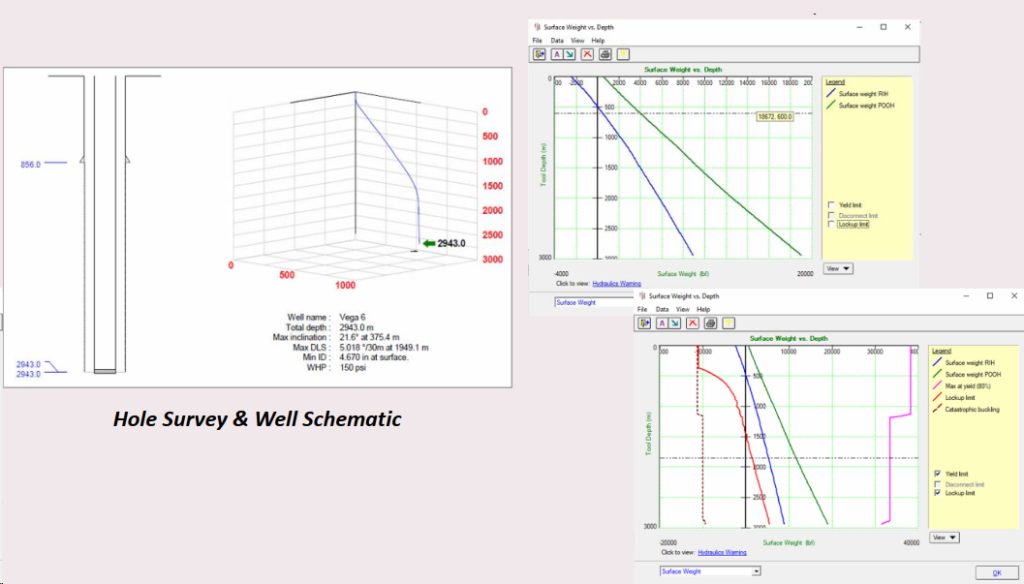

The Coiled tubing module allows the user to input basic and important data about the wellbore geometry, deviation and equipment to be used, allowing a virtual comprehension of downhole conditions and to make a simulation or real conditions of expected parameters during the execution of the job.

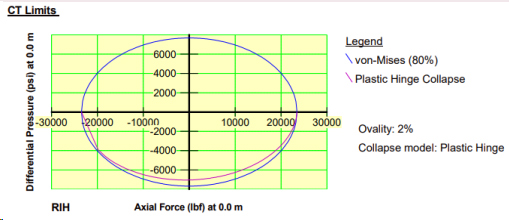

The three principle stresses and the shear stress experience by the CT during a job are combine using the Von Mises Yield Condition to determine what pressure and axial force combinations will cause the CT to yield.

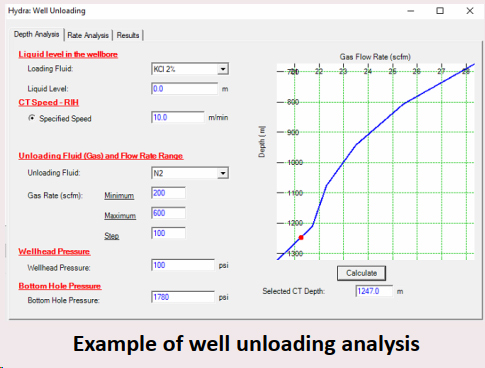

Hydraulics Simulation

Hypothetical fluid hydraulics situations may be modelled / calculated to determine the effects of differing variables such as type of fluids and pump rate.

Fatigue Life Tracking

Viewable in the screen are the different factors affecting fatigue life and diameter growth. In every trip the operator can recognize high fatigue points and make decisions to optimize the use of the string.

Tubing Forces Model and Stress Limits

An accurate calculation of the surface weight vs. depth is displayed in a graph as the CT is run into the well and out of the well. From the graph the user may calculate Yield Limit, Disconnect limit and Lockup limit.

The Hydra module use wizard applications to calculate data of particular type of jobs:

Job reporting

Based on the job parameters measured during the operation a post job report can be personalized to show a summary of job parameters acquired during the execution.

Mobile coiled tubing unit

Custom work floor minimising load transfer to well head